- Shipping Company Estimated Delivery Time Shipping Cost

Highlights

Mecpow X3 Pro 10W Laser Main Features

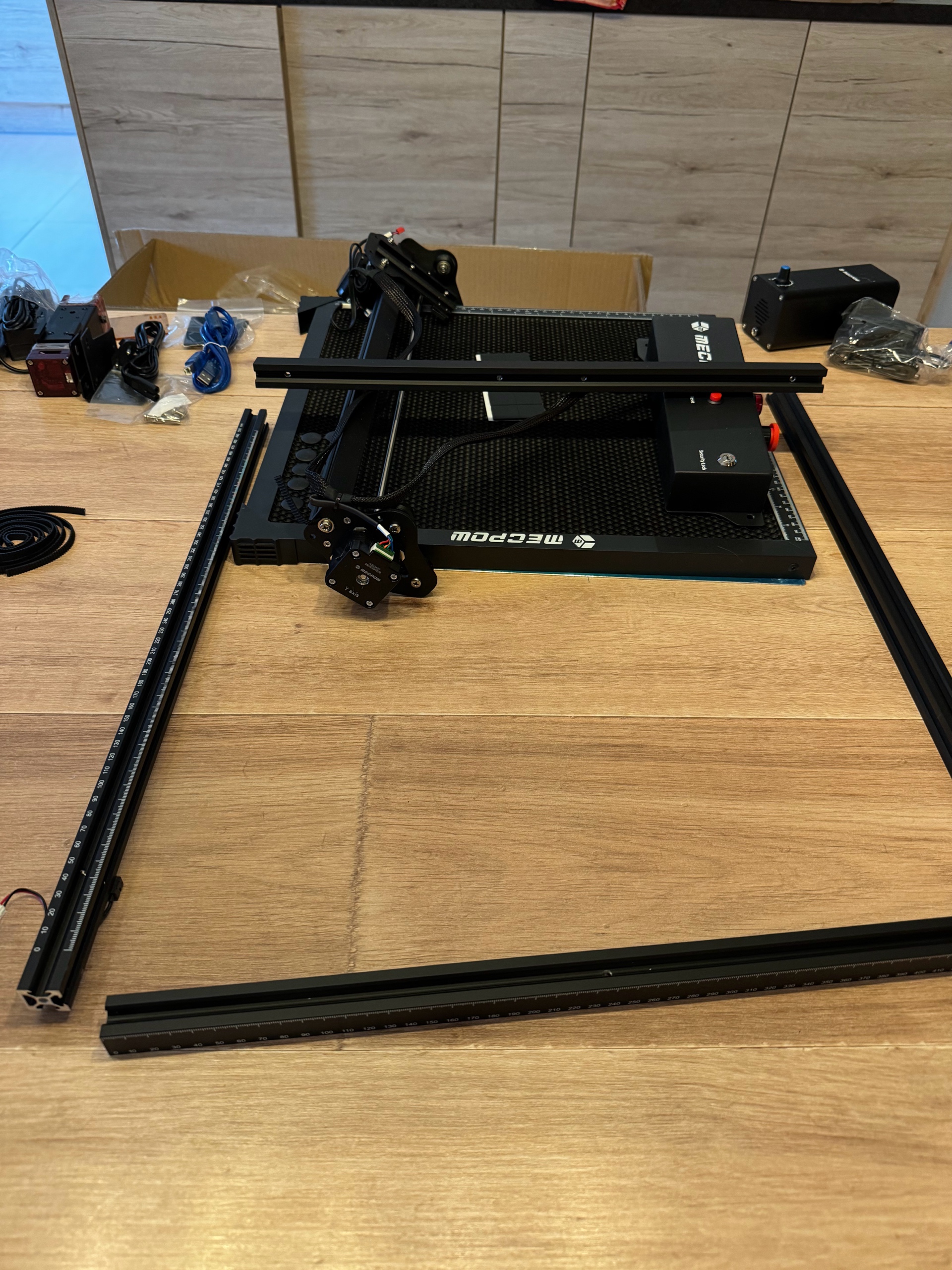

Mecpow X3 Pro is one of the world's first 10W laser engravers with an air assist system included, therefore its cutting capacity is greatly improved compared to its counterparts. Plus, the cutting accuracy and cutting quality are also optimized to a great extent.

- 10W Laser power

- 0.01m engraving accuracy

- 0.06x0.08mm compressed spot

- Flame sensor and tilt alarm

- Security lock

- Limit switches

- Fixed Focus

- Air assist and Air pump included

High-Precision Engraving

The Mecpow X3 Pro adopts a 10W diode laser with a small focus of 0.06x0.08mm, along with an engraving accuracy of 0.01mm to produce high peak power, ultimately achieving more accurate and deeper engraving and cutting. It can cut a wood board with a 20mm thickness and an acrylic board with a 15mm thickness.

Security Protection

The X3 Pro machine boasts a flame sensor and a gyroscope sensor, which can trigger the alarm and stop the machine’s operation in the event of a fire or tilting more than 50±5°. Besides, limit switches are included to prevent accidents and reduce wear by stopping the machine from moving beyond its safe limits, leading to a longer lifespan of the laser engraver. Furthermore, you can stop the machine anytime by pressing the emergency stop button and locking the machine to keep it safe from unwanted use, which is especially handy if you have kids around.

Adjustable Air Assist Pump

The attached air pump helps to remove debris and smoke for a cleaner cut. It also prevents the buildup of combustible materials, reducing the risk of fire and providing a safer engraving experience. Plus, with its adjustable knob, you can easily regulate the airflow according to the density of the smoke for a smokeless and odorless workspace.

Fast & Easy Focusing

The X3 Pro laser engraver comes with a fixed-focus laser that saves you time in adjusting the focus and a focusing screen that helps you move the laser head to the correct position. Slide down the laser head till it touches the focusing screen on the object and then remove the focusing screen.

Eye Protection

The laser engraving machine is equipped with a laser shield on the laser module, which can filter out diffuse light from the laser spot to a large extent. A pair of laser safety goggles is also included for better eye protection.

Wide Application and Compatibility

The X3 Pro engraving machine can be used for engraving on a variety of materials, including wood, acrylic, leather, bamboo, fabric, stainless steel, etc. It is compatible with LaserGRBL (Windows only) and LightBurn (Windows and Mac OS), supporting various file formats, including JPG, PNG, DXF, TIF, PDF, SVG, AI, NC, BMP, etc.

Specifications

|

General |

Brand: Mecpow |

|

Specification |

Frame Material: High-Strength Aluminium Alloy |

|

Features |

Alarm: Yes |

|

Weight & Size |

Product Weight: 3.67 kg |

|

Package Contents |

1 x Laser Engraving Machine (Unassembled) |

Mecpow X3 Pro Recommended Settings

| Material Name | Thickness(mm) | Processing | Power(%) / Speed(mm/s) / Pass |

|---|---|---|---|

| Plywood | 3MM | Cutting | 480mm/min 1 passes power 100% Air On |

| Plywood | 6MM | Cutting | 180mm/min 1 passes power 100% Air On |

| Plywood | 10MM | Cutting | 180mm/min 4 passes power 100% Air On |

| Plywood | / | Engraving | 3000mm/min power 30% |

| Basswood | 3MM | Cutting | 360mm/min 1 passes power 100% Air On |

| Basswood | 6MM | Cutting | 180mm/min 1 passes power 100% Air On |

| Tung board/cork | 10MM | Cutting | 300mm/min 2 passes power 100% Air On |

| Tung board/cork | 15MM | Cutting | 180mm/min 2 passes power 100% Air On |

| Tung board/cork | 20MM | Cutting | 300mm/min 10 passes power 100% Air On |

| Black Acrylic | 6MM | Cutting | 180mm/min 2 passes power 100% Air On |

| Black Acrylic | 11MM | Cutting | 180mm/min 11 passes power 100% Air On |

| MDF | 3.6MM | Cutting | 240mm/min 2 passes power 100% Air On |

| MDF | / | Engraving | 3000mm/min power 15% |

| Stainless steel | / | Engraving | 360mm/min power 100% |

| g Kraft paper | / | Engraving | 1800mm/min power 15% |

| Leatherwear | / | Engraving | 1800mm/min power 10% |

Videos

Customer Photos

Customer Videos

Customer Reviews

| 5 star | 129 | |

| 4 star | 6 | |

| 3 star | 1 | |

| 2 star | 0 | |

| 1 star | 0 |

- All (136)

- Images (17)

- Videos (0)

Questions & Answers

FAQ

1. LaserGRBL and Lightburn fail to connect to the laser engraver after successful driver installation.

Check if the Emergency Stop button is pressed. If it is, turn it clockwise to pop it up and then reconnect the laser engraver.

2. The LaserGRBL software suddenly stops during the engraving process.

A. Check whether the product is still connected to LaserGRBL.

B. Check whether the power supply is on and whether the red indicator light on the laser module is on.

C. Check whether the driver is installed successfully.

3. LaserGRBL fails to connect to the product.

A. Check if the driver has been installed on the computer.

B. Confirm whether the baud rate is 115200 and the port selection is COM3.

C. Check whether the USB cable is not plugged properly or damaged. Replace the USB cable if it is damaged.

4. The machine moves normally, but the laser does not light.

A. Check whether the wire connecting to the laser module is loose;

B. Adjust the laser power to the maximum.

5. Engraving or cutting does not achieve the desired effect.

A. Check if the laser focal length is correctly adjusted.

B. To achieve a better effect, we suggest following the recommended operating parameters in the user

manual.

C. Check if the laser lens is covered by foreign objects and keep it clean and clear.

D. Confirm whether the software settings are wrong (for Lightburn).

E. If the material for engraving or cutting is distorted and uneven, please ensure it is flat and even before proceeding.

F. The cutting speed is not recommended to be lower than 120 mm/min. For cutting thicker materials, we suggest cutting them in separate passes. If the speed is too low, it may cause serious burning around the cutting edge.

6. LightBurn fails to connect to the product.

A. Make sure the driver has been installed. You can install it from the following link:

https://mecpow.com/pages/driver-files. Once the driver is successfully installed, you should see "COM3" in the port selection.

B. Check if the baud rate is 115200.

C. Check whether the USB cable is plugged improperly or damaged. Replace the USB cable if it is damaged.

7. The LightBurn software suddenly stops during the engraving process.

A. Check that the product is still connected to LightBurn.

B. Check if the power supply is on and the the red indicator light on the laser module is on.

8. The alarm sounds and flashes.

A. Check if the emergency stop button is pressed. If yes, turn it clockwise to pop up the emergency stop button.

B. Check if the flame sensor is triggered by a fire in the engraving area.

C. Check that the engraver is not tilted beyond 50±5° and triggering the alarm.

D. If all the above problems are settled, press the reset button to reset the machine.

9. What are the causes of frequent false alarms?

Bright light or direct sunlight may cause the flame sensor to falsely trigger the alarm. Reducing the ambient light brightness can effectively avoid false alarms. If you can't change the ambient light brightness, please switch off the flame sensor.

10. How to set up LightBurn so that the the laser head does not return to the home position after power on?

Click "Edit" - "Machine Settings" and a window will pop up. Switch the homing cycle from "True" to "False". Then click the "Write" button below and click "OK" to complete the setting.

11. The engraved image is distorted.

A. The timing belts are not tightened, resulting in slippage.

B. The wheels are loose, causing slippage.

C. The timing belts or pulleys are defective.

12. The laser does not stop moving after hitting the limit switch.

A. The connection of the limit switch is poor. Re-connect it.

B. Check if the limit switch is damaged.

13. There are noises during the engraving process.

A. Check if the noise is coming from the motor. If it is coming from the motor, replace the motor.

B. Check whether the screws on both sides of the X-axis are fixed tightly.

14. What is the MicroSD port on the control box used for?

A. It is mainly used for updating the firmware of the engraving machine.

B. When using the app to control the engraving machine, it is necessary to store the engraving files in the MicroSD card and insert the card into the MicroSD port.

15. Does the machine require maintenance?

A. The laser module has a regular life expectancy of 10,000 hours or more. The service life can be affected by the environment. When the lens of the laser module is found to be scorched yellow or blurred, it needs to be replaced.

B. Regularly check the fit tightness of the timing belts and pulleys.

C. Regularly check whether the belts are notched or bent. The belts are equipped with steel wires, and bending is likely to cause the wires to break.

16. Can the engraving machine engrave on the metal surface?

For stainless steel, laser engraving can be done directly on its surface. Other metals, such as iron, aluminum, and copper, can only be carved with a coating applied to their surface.

17. Can the product cut through metal?

No.

18. How to maintain the laser module?

A. Maintain the laser head by regularly cleaning or replacing the lens.

B. The regular service life of the laser module is more than 10,000 hours. For better engraving effects, we recommend that you replace the laser module after use of 10,000 hours.

19. How to make sure that the engraving range is within the engraved object?

Click "Frame" to preview the engraving range. If the engraving range is beyond the engraved object, move the object or the laser head to adjust it.

20. Can the engraving machine be used on an iPad?

No.

21. Can the machine engrave on glass or ceramics?

Yes. Glass needs to be painted on the surface and ceramic needs to be applied with heat transfer paper on the surface.

22. Is it possible to engrave on coating layers?

Yes. For coated layers, the engraving speed must be fast. For grayscale images, we recommend that you use LightBurn for engraving. Grayscale engraving with LaserGRBL is much slower, so the engraving results will not be as good.

23. Can you engrave on a 3D object, such as a water bottle?

Yes. It needs to be used with a rotary roller. Connect the rotary roller to the Y-axis motor.

24. How often should I replace the lenses of the laser module?

Smudged lenses can seriously affect the quality of engraving or cutting. Thus, we recommend that you replace the lenses once a month.

25. What if the laser module is not raised high enough?

Loosen the screws in the dovetail groove on the back of the laser module. Then move the dovetail groove down to the screw holes below. Insert the screws into the screw holes and tighten the screws to secure the dovetail groove.